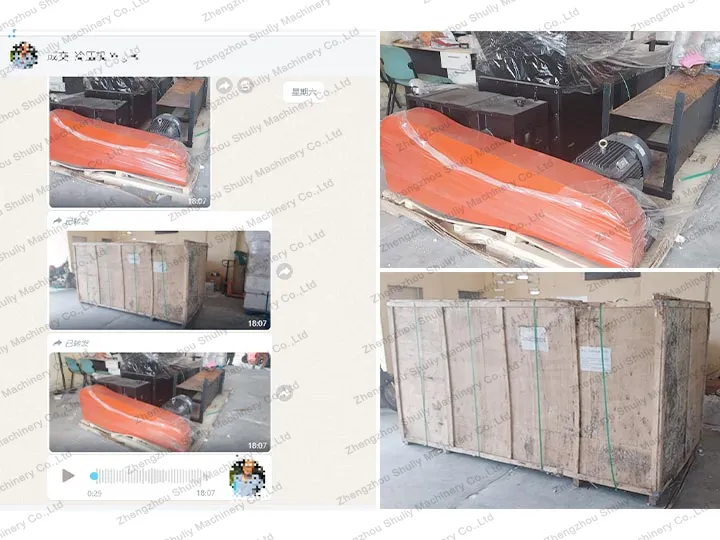

Good news! The EPS foam compactor purchased by the customer has been delivered to his factory and he sent us pictures of the unboxing.

Basic information about EPS foam compactor

- Location: Malaysia

- Machine: EPS styrofoam recycling compactor

- Quantity: 2

- Feeding method: Top feeding

- Delivery method: Delivery to your door

- Raw material: EPS foam

- Finished product: Foam briquette

Parameters of foam packaging equipment

| Name | EPS foam compactor |

| Model | SL-400 |

| Machine size | 3200*1600*1600mm |

| Input size | 870*860mm |

| Power | 22kw |

| Capacity | 300kg/h |

Shuliy Group’s attentive service

This customer from Malaysia has his own factory and this time he is going to buy two foam packaging equipment. He has been in the plastic recycling business for several years. Shuliy’s sales manager asked the customer whether he wanted a hot melting machine or a cold press machine, and the customer said he preferred an EPS styrofoam recycling compactor. After confirming the customer’s needs, our sales manager sent pictures and videos of the machines to him.

The customer chose to buy the model SL-400 with a production capacity of 300kg/h. After the customer told us the voltage standard in Malaysia, Shuliy customized the motor with a voltage 415v 50hz 3p. Normally, the machine voltage is 380v 50hz 3p.

Shuliy’s sales manager responded to the customer’s concerns in a timely manner and answered his questions seriously. The customer was deeply affected by our warm service and professional knowledge. Finally, he decided to purchase two pieces of foam packaging equipment. Shuliy Group is indeed a trustworthy machine manufacturer!