Plastic bottle washing line plays a key role in cleaning, crushing, and recycling plastic bottles for further processing. The benefits of timely and effective maintenance include increased efficiency, longer equipment life, and reduced downtime.

In short, plastic bottle washing lines are an important part of the plastics recycling industry. By following these daily maintenance and care guidelines, you can ensure that your line is running at peak performance, reducing costs and minimizing downtime.

Why plastic bottle washing line regular maintenance?

Plastic bottle washing line equipment works every day, and regular inspection of machine components can identify and resolve a number of potential problems with the machine in a timely manner.

By following routine maintenance and care guidelines, you can increase the efficiency and longevity of your PET bottle cleaning line. This can reduce costs, minimize downtime and improve the quality of the bottle output.

Regular inspections, effective maintenance procedures, and quick problem-solving strategies are essential to maintain a successful PET bottle cleaning line.

Daily maintenance of plastic bottle washing line

- Check the machine parts before running the production line. If the machine is found to be loose, make corresponding treatment in time

- The flow line must work every day for a certain period of time. Equipment will produce a lot of rust after a long time, the next use will bring a lot of trouble, put a long time will reduce the life of the equipment

- Private modification is prohibited. The operation of each piece of equipment is strictly in accordance with the equipment manual

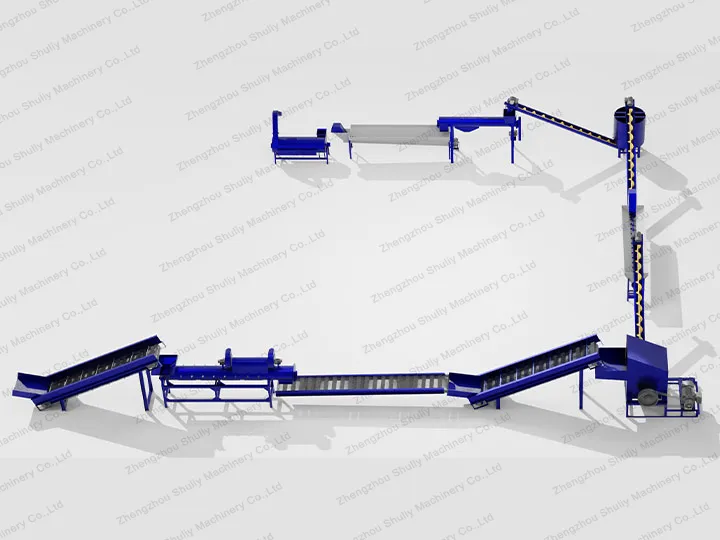

What equipment does plastic bottle washing line include?

Delabeling machine: The delabeling machine is used to remove the labels from plastic bottles

PET crusher: The crusher is used to break the PET bottles into smaller pieces to make them easier to clean

PP PE separating tank: The sorting tank is used to separate the pp bottle caps from the pet pieces

Hot water washing machine: The hot wash pot removes residual dirt and contaminants from the bottle pieces by using hot water and chemical detergents

Plastic friction washer: The friction washer is used to further clean the bottle pieces and remove the chemical detergent residue on the bottle pieces

Rinsing tank: The rinsing tank is the final cleaning process to obtain PET flakes

Dryer machine: The drying machine is used to remove the residual moisture on the bottle flakes after cleaning

These are the key pieces of equipment for a complete plastic bottle recycling line. The specific equipment used may vary. It depends on the capacity of the line, the type of bottles being processed, and other factors. All machines can be customized by Shuliy Group. For more information on the machines, please contact us to obtain them.