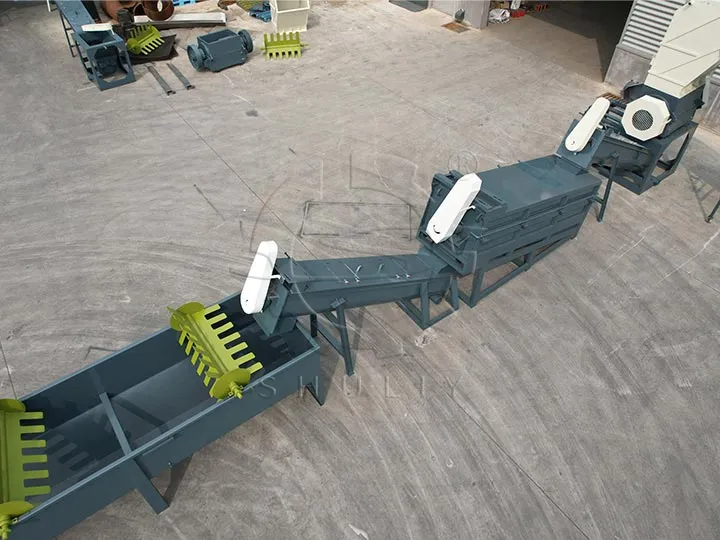

A plastic film recycling washing line, also known as a PE film washing machine, crushes plastic waste into small pieces, then washes and dries them. The plastic recycling washing line is suitable for all kinds of PP, PE, PET, HDPE, PVC, LDPE, and other recyclable waste plastics with economic value.

A plastic recycling washing line consists of several machines, mainly including a plastic crushing machine, rinsing tank, plastic dryer machine, storage bin, and so on.

What is Plastic Film Recycling Washing Line?

Plastic PE film washing machine is a specialized equipment for cleaning PE (polyethylene) film, mainly for the waste PE film recycling process of cleaning links, can effectively remove the film surface dirt, impurities, residual chemicals, etc., so that it restores the clean state, to subsequent recycling and reuse.

This PE film washing machine has high production efficiency and a good cleaning effect. The moisture of plastic after drying is less than 5%.

Production Process of Plastic Recycling Washing Line

The production process of a plastic film pelletizing machine is a systematic process designed to clean and process waste plastics, making them suitable for reuse.

| NO | Process | Machine | Description |

| 1 | Crush plastic film into small pieces | Plastic crushing machine | The plastic crusher machine cuts the waste plastic film into small pieces of about 10-20 millimeters in size and moves them to the next machine. |

| 2 | Delivering plastic film pieces to the rinsing tank | Screw conveyor | Installed on the plastic crusher machine for conveying materials |

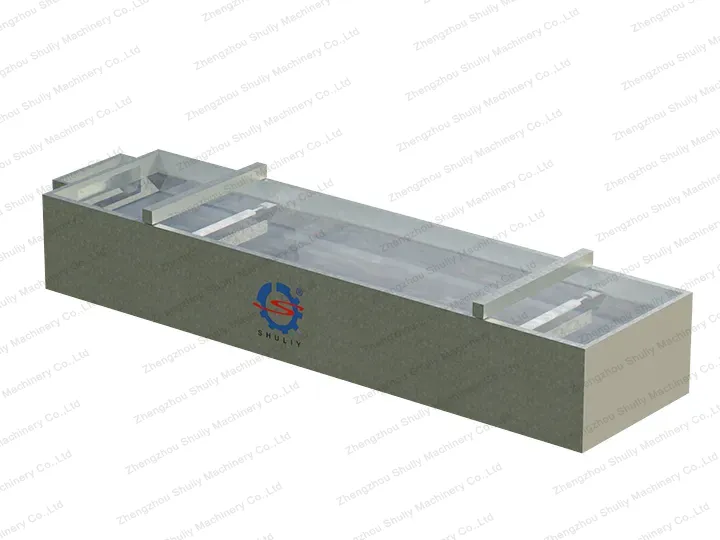

| 3 | Washing plastic film chips | Washing tank | Remove debris from plastic film mixed with dirt and wood chunks. If the material is too dirty, add more rinsing tanks. |

| 4 | Drying the plastic film | Plastic dryer machine | Plastic dryer machine utilize centrifugal force to shake off water from the film. |

| 5 | Store dry films and bags | Storage bin | Used to store clean, dry plastic film as raw material for plastic pelletizing machines |

Plastic Recycling Washing Plant Working Video

The operating principle of PE film washing machines usually combines mechanical force, water flushing, heating, and chemical cleaning.

This video is about the plastic pelletizing line filmed in the field. It describes how the plastic recycling washing plant operates, including a belt conveyor, a plastic washing machine, and a plastic shredder.

Main machines of PE Film Washing Machine

PE film washing machine is the key equipment combination to convert waste plastic film (such as PE agricultural film, PP packaging film) into clean recycled material, mainly including feeding and conveying, crushing pretreatment, deep cleaning, dehydration and drying, granulation and cooling of the five systems, through the mechanical force, water flushing, heating and chemical additives synergistically, to achieve the removal of dirt and recycling of resources.

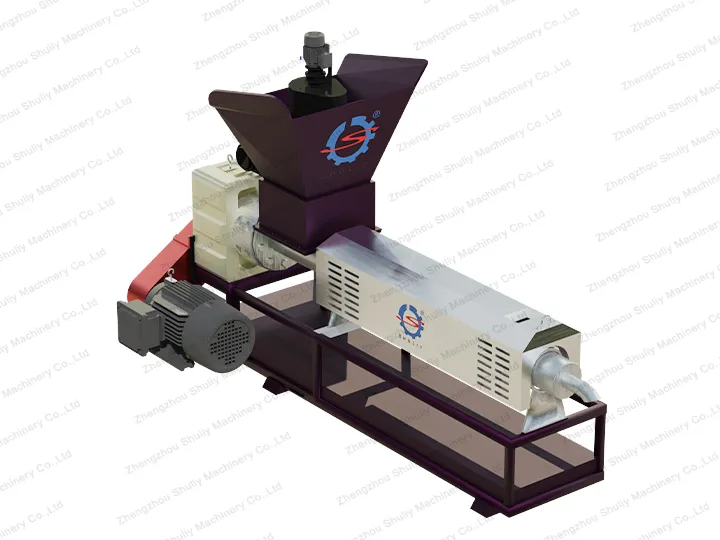

Plastic Crusher Shredder Machine

Rolls or large pieces of plastic film are broken into 5-10 cm pieces for subsequent cleaning and melting.

Plastic Washing Machine

Removes dirt, ink, mud, and other impurities from plastic chips by hot water, detergent, and mechanical agitation.

Plastic Dryer Machine

The dewatering conveyor in the PE film washing machine separates the water from the plastic film by centrifugal force.

Above is the PE film washing machine. But our factory also provides plastic film pelletizing equipment.

After the waste plastic film is crushed and cleaned, it is heated and melted by the screw extruder, extruded from the die head into fine strips, into the water tank for cooling and curing, and then cut into pellets by the pelletizer.

Plastic Film Pelletizing Machine

The cleaned plastic film is melted into a paste at high temperatures, and then the molten plastic is extruded into thin strips through the die.

Cooling tank

Rapid cooling and shaping of the extruded plastic strip, the water temperature is controlled at 20-30 ℃, to avoid pellet sticking.

Plastic Pellet Cutting Machine

Cut the cooled thin strips into evenly sized pellets

Plastic pellet storage bin

It can provide a relatively closed space for the material to avoid the particles being polluted by the external environment (such as dust, moisture, etc.) and protect the quality of the material.

The exact machine configuration of the woven bag recycling machine can be adjusted to suit your needs. If you need, you can contact us at any time.

Plastic Washing Line Application

The main application areas of our plastic recycling washing lines are:

- Agricultural films

- Packaging film

- Stretch film

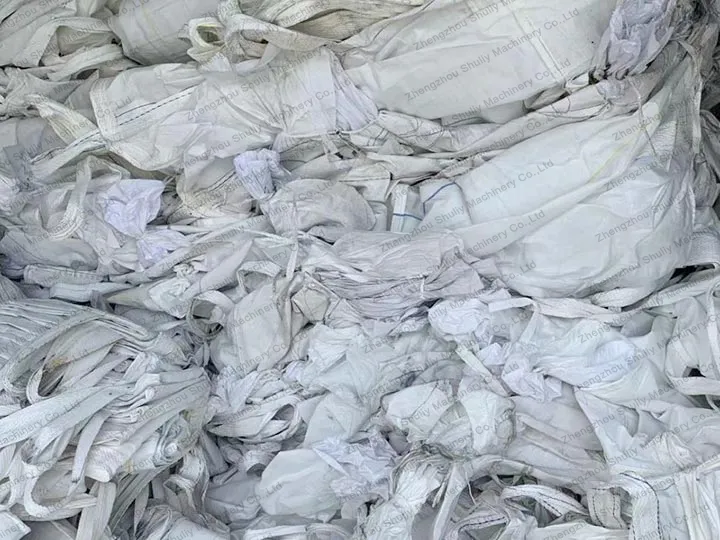

- PP bags (big bags, raffia bags)

- PET bottles

- Fruit, vegetable, and bottle boxes

- All types of rigid plastics

- Plastic bumpers

- Appliance housings

- Plastic containers and buckets

- PVC plastic window frames

Features of Plastic Film Recycling Washing Line

- The plastic washing line can be designed according to the degree of soiling of your raw materials to ensure the quality of the final product.

- The plastic film recycling washing line works in conjunction with the subsequent granulation work to make plastic pellets from waste plastic film and woven bags.

- Our plastic washing line is easy to operate and has low consumption.

- Plastic washing plant after drying plastic’s moisture content is less than 5%

Set up a Plastics Washing Plant

This plastic film recycling and washing line is an integrated solution designed to convert waste plastic film into reusable raw materials. It integrates several functional units to form a streamlined production process that efficiently handles various types of waste plastic films, such as agricultural, packaging, and industrial plastic films.

Our plastic film recycling washing lines are designed to reprocess waste plastics. We can also provide specific customized cleaning and recycling solutions based on the nature of the raw plastic material and your application requirements. Feel free to leave a message on our website if needed.

FAQs of PE Film Washing Machine for Sale

What causes the incomplete cleaning of plastic film recycling machines?

Insufficient water temperature or short washing time, or insufficient mechanical agitation.

How to solve the problem of lumping plastic pellets after drying?

Reduce the hot air temperature to 80-90°C and increase the frequency of material stirring.