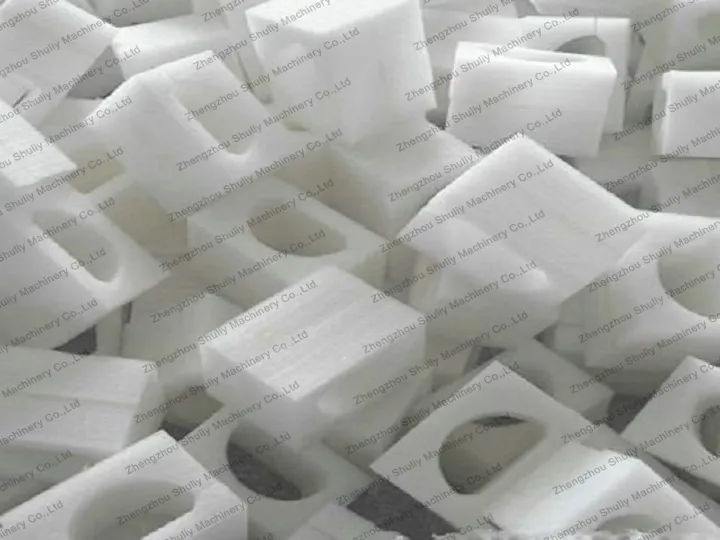

EPE pelletizer is to make recycled plastic granules from waste EPE foam through the process of crushing, melting, extruding, pelletizing, and cooling.

Working Video of EPE Styrofoam Pelletizing Machine

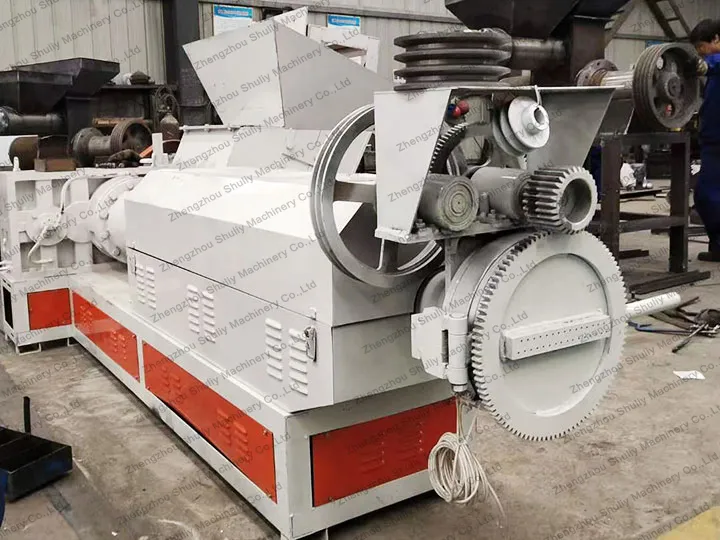

Introduction of EPE Styrofoam Pelletizing Machine

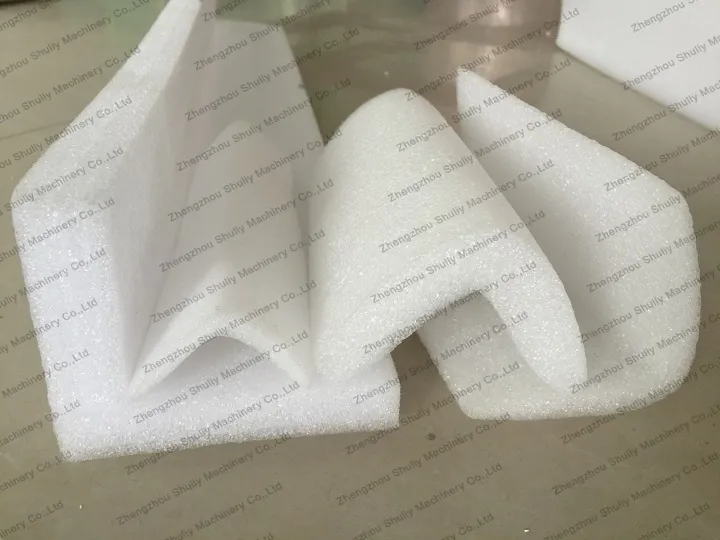

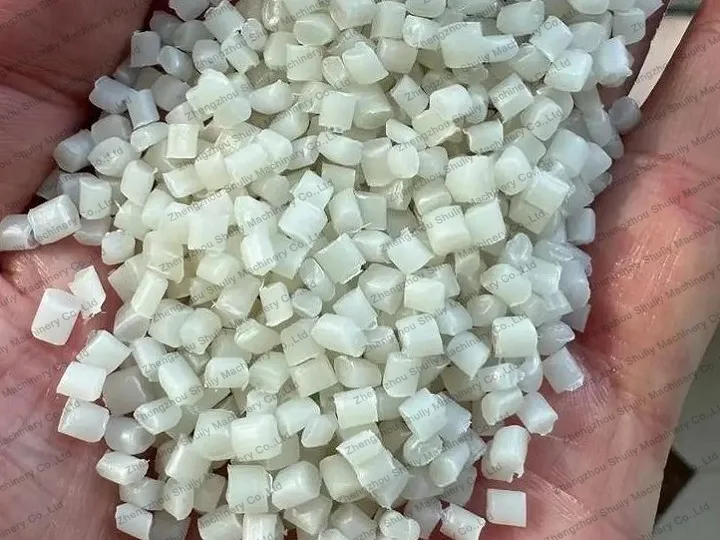

EPE Styrofoam Pelletizing Machine, also known as plastic foam granulators, can produce plastic pellets without destroying the original molecular structure. The pellets produced are widely used.

EPE granulator is suitable for the extrusion and granulation of EPE foam raw materials, which can be used for the regeneration of EPE foam. Shuliy plastic foam granulator adopts an exhaust structure to exclude the gas produced in the plasticizing process, which makes the granules dense and smooth surface. The production operation is very simple and the investment cost is very low, but the economic benefit is high.

Main Parts of Styrofoam Recycling Machine

Feeding Conveyor

The feed inlet adopts a large-diameter direct-entry design, which is suitable for direct feeding of soft EPE materials without pre-crushing, with high feeding efficiency and convenient operation.

Heating Ring

The heating ring is to melt the foam and convert it into a paste so that it can smoothly pass through the die head.

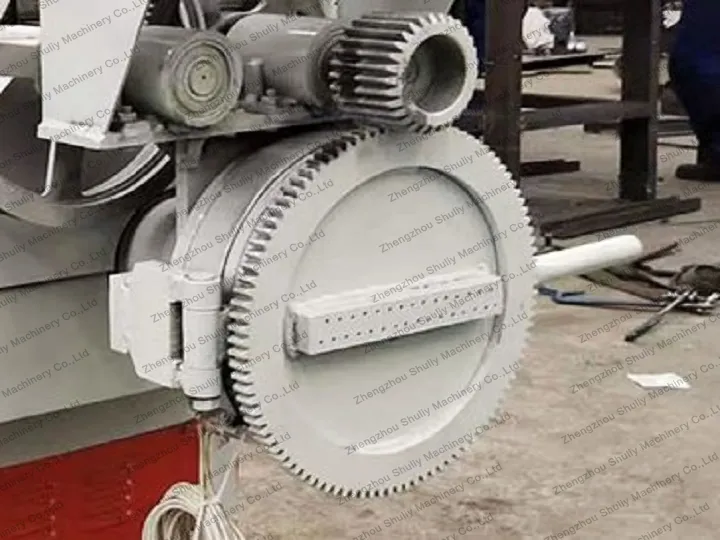

Die Head

The die head extrudes the molten foam through its internal holes into stripes for subsequent cutting.

EPE Styrofoam Pelletizing Machine Parameters

| Item | Details |

| Pellet making machine | Pellet-making machine |

| Water tank | Length: 4m |

| Pellet cutting machine | Power:1.5kw |

If you want to know more details, please feel free to contact us!

EPE Foam Granulating Line Process

When the EPE styrofoam pelletizing machine is working, the waste EPE foam is first put into the machine from the feeding port, and then crushed into small pieces by the crushing unit.

Then it enters the core part of the pelletizing machine, and the heating unit heats the broken pieces to the molten state.

Subsequently with the paste into the screw area in the EPE styrofoam pelletizing machine, the screw is pushed it to the die to be extruded into a long strip;

The long strip of material into the cooling tank quickly cooled and cured; finally, by the pelletizer, it was precision-cut into small particles for easy storage and transportation.

Operation methods of EPE Styrofoam Pelletizing Machine

- There are two heating circles on the upper and lower screw of the EPE styrofoam pelletizing machine, and each heating circle has a switch, which can be opened and closed at will according to the temperature needed for processing.

- When the foam granulator is working, first heat the upper and lower barrels for 20-40 minutes, then take a piece of foam on the machine head and press it lightly, if the foam can become soft and melt, it means that the barrel heating has reached the working temperature, and the machine can be turned on.

- Add a small amount of foam to the hopper first. If the extruded material has melted, only then can a large amount of material start working. If the temperature is found to be too high during the work, you can cut off the head heating power and continue to work.

- In the plastic foam granulator work, the lower screw head can add a layer or two layers of filters as needed. A strainer should have more than one when working; if the strip is not smooth, it means that the strainer is clogged, so replace the strainer in time. The steel filter screen can be recycled by removing impurities after burning with fire.

EPE Foam Granulator Line Solution

The EPE styrofoam pelletizing machine can be combined with auxiliary equipment such as crushers, dryers, and extruders to form a complete production line–EPS Foam Granulating Line.

Plastic Foam Crusher

Crush the waste EPE foam into small pieces for subsequent cleaning, melting, and other processing.

Plastic Pellet Cutting Machine

cuts the cooled EPE strips into pellets of a specified size to form preliminary finished products.

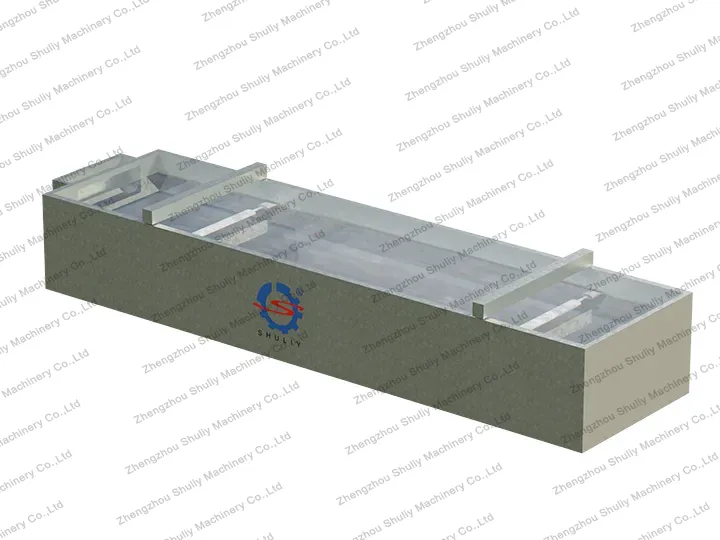

Cooling Tank

to cool and solidify the extruded EPE melt strip quickly, to prepare for the pelletizing process.

Plastic Granule Storage Bin

temporary storage of qualified pellets after drying and screening, which is convenient for subsequent measurement, packaging, and unified storage.

The specific configuration of the EPE styrofoam pelletizing machine line can be customized according to your requirements and needs. If you want to know more, please leave a message with us on the website, and we will contact you in time.

How to Choose Right EPE Foam Granulator?

Shuliy EPE styrofoam pelletizing machines are available in a variety of models with outputs ranging from 150-500kg/h. To select the right machine for your plant, you should consider the following questions:

- Details of what you want?

- What are your raw materials?

- Do you have a stable source of raw materials?

- What is the end product you want to produce?

- What machine capacity do you want it to perform?

Features of Plastic Foam Granulator

- Free assembly of screw assembly according to material type

- High-efficiency forced feeder to ensure high capacity feeding stability and low power consumption

- Main screw with vacuum exhaust function

- Single-screw extruder with specially designed screw, barrel, and exhaust system to ensure good quality of the final product

Advantages of Shuliy Plastic foam extruder

- Precise matching of production capacity: The production of the EPE styrofoam pelletizing machine ranges from 150 to 250kg/h, suitable for small workshops to medium-sized factories.

- High-quality service: Online installation guidance and other training services are available, as well as on-site installation guidance upon request.

- Modularity: Customized design for stand-alone use or integration into complete systems with plastic crushers and compactors, or even into washing lines

Suriname Installs Two Styrofoam Recycling Machines

Two Styrofoam recycling machines have been successfully installed in Suriname for recycling foam packing materials. Thanks to the availability of models and components in stock, the machines were shipped within 25 days of the order placement. Prior to shipment, engineers conducted thorough testing and inspection to ensure their smooth operation.

The installed machines include the SL-160 EPE recycling machine and the SL-220 EPS pelletizer, which are designed to process styrofoam and expanded polyethylene packing materials. They are applicable for both post-industrial and post-consumer recycling. The core configuration equipment comprises a cooling tank, a pellet cutting machine, and a styrofoam shredder. This installation highlights efficient delivery and professional pre-shipment preparation to facilitate foam recycling in Suriname.

Why Recycle EPE Pearl Cotton through Plastic Foam Extruder?

With the application of raw materials becoming more common, the resulting increase in pearl cotton waste, and EPE pearl cotton recycling has become an urgent need to solve the problem of many enterprises. Many people see the business opportunity in this, so the EPE pelletizing business began. Shuliy has an EPE pelletizer for sale that can help you start your plastic foam pelletizing business. Welcome to contact us.

EPE pearl cotton has high-quality impact resistance and reinforcement. It is widely used in high-grade furniture, household appliances, instruments, and meters, wooden furniture, porcelain, building waterproofing projects, etc. It is an ideal material.

FAQs of EPE Styrofoam Pelletizing Machine

What are the common causes of unusual noise in the EPE Styrofoam Pelletizing Machine?

Worn bearings/insufficient lubrication, uneven screw-barrel gap, or loose fasteners.

What causes a rough granule surface?

Impurities/wet raw materials, low die head temperature

Why can’t the granulator heating temperature stabilize?

Partial damage to heating coils, causing uneven local temperature.