Friction washing machines, designed for friction washer plastic recycling, are very effective for contaminated plastic flakes and films. It can be integrated or retrofitted into your recycling pelletizing and washing lines.

Introduction of Friction Washing Machine

The Friction Cleaner is an advanced piece of equipment designed to clean a wide range of materials using the principle of friction. It has become an essential tool for industries such as plastics recycling, metal processing, and textile manufacturing, significantly improving the efficiency and quality of the cleaning process.

PET bottle flake friction washing machine is mainly used for PET bottle flake cleaning and conveying. The broken bottle flakes are fed into the friction washer by the screw loader. The screw rotates under the drive of the motor, and the bottle flakes move forward and get cleaned under the push of the blades.

How do Friction Washers Work?

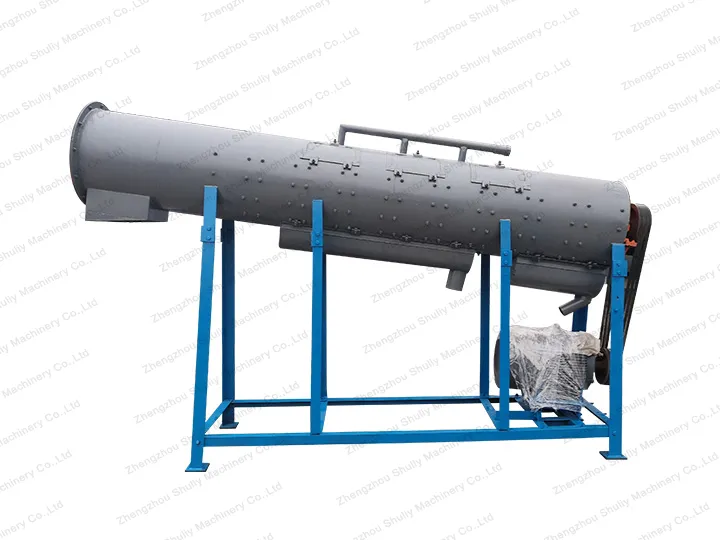

The high-speed friction washer consists of a high-speed rotor surrounded by a removable screen. The high-speed rotor ensures that the material is “scrubbed” and “tapped” inside the screen. Multiple nozzles spray water onto the screen to continuously remove contaminants and dirt. The contaminants and dirty water are then discharged through the perforated screen and collected at the bottom.

Plastic friction washers are placed at a 45-degree angle to maximize friction and carry out impurities and contaminants.

Process of Plastic Bottle Washing Machine

A friction washing machine works on a principle that combines mechanical friction with water rinsing. There are high-speed rotating parts inside the machine, such as propeller blades or friction plates.

Step 1: Friction stripping impurity treatment

When the plastic bottles enter the machine, driven by the rotating parts, strong friction will be generated between the bottles and between the bottles and the friction parts, which can strip off all kinds of impurities attached to the surface of the bottles.

Step 2: Water flow-assisted rinsing and cooling treatment

At the same time, the machine will be injected into the internal water, water flow on the one hand to assist in rinsing off the impurities being rubbed down, on the other hand, also play a cooling effect, to prevent the plastic bottle pieces due to the friction of heat and deformation or melting.

Plastic Friction Washer Structure

- Rotating parts: mostly made of high-strength stainless steel, commonly a spiral paddle or a friction plate with a special pattern.

- Cleaning cylinder: The cylinder is usually made of thick carbon steel or stainless steel, with good wear resistance and corrosion resistance.

- Water supply system: It contains components such as water inlet pipe, spray nozzle, and so on. The water inlet pipe is responsible for introducing clean water into the machine, while the spray nozzle sprays the water at a specific angle and pressure.

Plastic Bottle Recycling Line Solution

By using the Friction washing machine in conjunction with the plastic washing machine and hot washing tank, a highly efficient cleaning system can be constructed.

In this system, the Friction washing machine utilizes strong friction to strip the material surface of impurities, the washing tank provides sufficient space for water rinsing, and the hot washing tank uses high temperature to further dissolve stubborn stains.

The three complement each other, can significantly improve the cleaning efficiency and cleanliness, to achieve far more than a single equipment operation of the cleaning effect.

Features of Plastic Friction Washer

- Fully disassembled box structure, easy maintenance of the whole machine

- The screen is made of stainless steel, with a long service life

- Simple installation structure and low maintenance cost of equipment

- Plastic bottle washing machine with an automatic overload protection system to ensure the safety and reliability of the equipment to the greatest extent

What can High Speed Friction Washing Machine be used for?

The high-speed friction washer is usually used behind the plastic bottle crusher. It can be used for washing PP, PE, HDPE, PVC, and ABS flakes.

In all kinds of recyclable waste plastic cleaning lines, most of them will apply plastic friction washers. The machine’s high-speed washing method makes it plays an important role in the plastic bottle washing recycling line.

Successful Installation of High-speed Friction Washers

High-speed Friction Washers are successfully sold to various countries. For example, Mozambique, Indonesia, Congo, and South Sudan.

Currently, the Friction Washers have been successfully installed in Mozambique and are working well to help Mozambique factories recycle PET bottles.

According to the feedback from the Congo factory, the frictional washing machine in Congo is running stably and efficiently, and has received a lot of favorable comments.

Friction Washing Machine Inquiry

We can provide you with a complete solution for your plastic bottle recycling line:

From raw material research and analysis to application site investigation, technical program design to overall engineering layout, from equipment production to the whole line installation and commissioning, we provide you with a one-stop service, so you can rest assured to carry out your own business.

FAQs of Friction Washing Machine

How to solve the problem of poor cleaning effect?

①Regularly inspect and replace worn friction components;

②Clean the nozzles and adjust the water inflow.

③Extend the cleaning time according to the degree of dirt.

④Feed the flakes according to the specified processing capacity.

What are the reasons for drainage and filtration system failures?

①Drainage pipe blockage;

②Drainage pump failure.

What are the reasons for abnormal equipment operation?

①Unstable equipment installation;

②Loosening or deformation of rotating components;