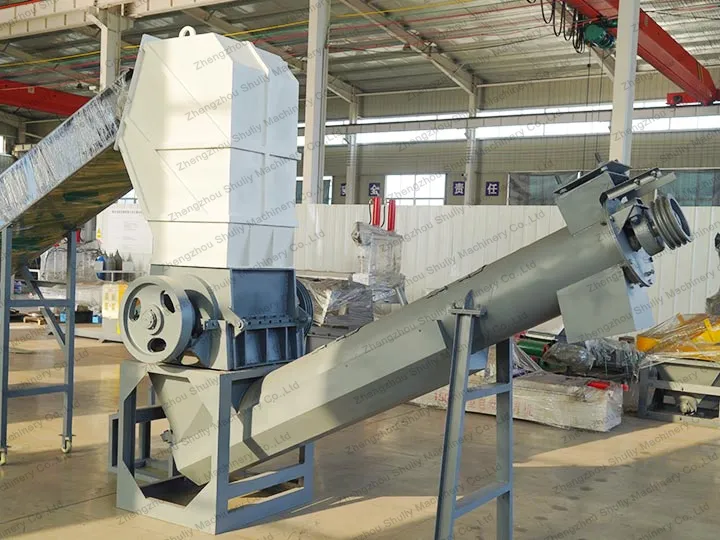

The plastic bag crusher machine is a plastic recycling equipment specially designed to process all types of plastic bags, plastic film, and plastic packaging waste.

Plastic Bag Crusher Machine Introduction

A plastic bag crusher machine is an indispensable configuration in the plastic bag recycling line. Because plastic bags are often thin, soft, and malleable, these waste materials require a plastic film shredder machine that can effectively crush, cut, and shred these materials.

Waste film crusher machines typically have small blade spacing and high-speed rotating blades to effectively cut plastic bags and other materials into small pieces or fine particles for subsequent reprocessing or recycling.

Workflow of Woven Bag Shredder

Step 1: Feeding

Put the plastic material into the feed hopper of the plastic bag crusher machine.

Step 2: Crushing

The material enters the crushing chamber, and is sheared and crushed by the movable knife and the fixed knife

Step 3: Discharging

The crushed pieces fall out through the screen and are discharged from the discharge port

Step 4: Collecting

The material can be collected manually or sent to the next process (e.g., cleaning, pelletizing) through the conveyor.

Waste Film Crusher Machine Working Video

Plastic Scrap Shredder Machine Structure Breakdown

- Feeding Hopper: Enlarged feeding port, convenient for feeding, suitable for large plastic or batch continuous feeding.

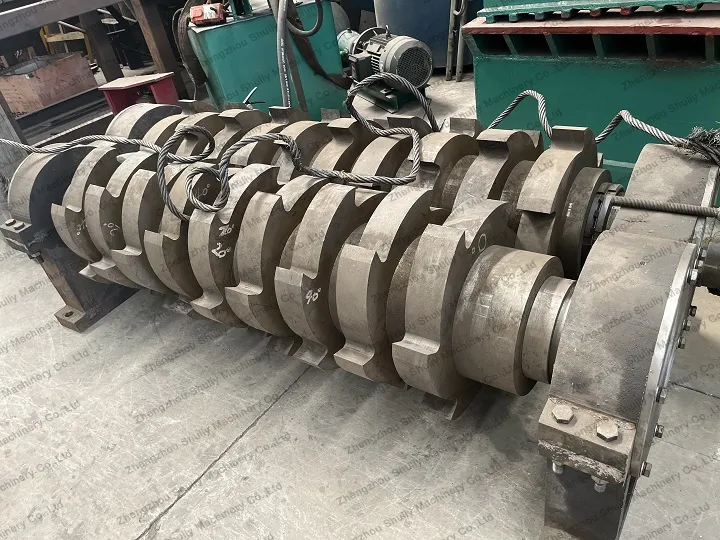

- Rotating Cutter: Installed with 6 movable knives, high-speed rotating cutting.

- Fixed Blades:4 fixed blades are fastened in the crushing chamber to enhance the shearing efficiency.

- Hydraulic Cylinder: Controls the upper cover to open automatically for easy maintenance or tool replacement.

- Screen Mesh: Can be customized according to the needs of different screen sizes to control the particle size of the material.

- Heavy-duty Frame: The whole machine is welded solidly, shock-resistant and impact-resistant, suitable for long-term operation.

Technical Specifications of Plastic Shredder

| Item | Specification |

| Model | SLSP-800 |

| Motor Power | 45 kW |

| Capacity | 800–1000 kg/h |

| Knives | 6 movable knives, 4 fixed knives |

| Blade Material | 60Si2Mn |

Shuliy has more than one model of plastic bag crusher machine. If you want to know more about other models, you can leave us a message on the website. We will contact you in time.

Plastic Bag Crusher Machine Related Equipment

Plastic film shredder machines can be paired with a variety of recycling equipment and plastic pelletizing lines for a more efficient plastic waste processing and recycling process. Here are some common pairing options.

Plastic pelletizer machine: If you want to further process the plastic bags into granular recycled plastic pellets, you can feed the shredded plastic bags into the pelletizer for pelletizing.

Plastic recycling line: Combine the waste film crusher machine with other plastic waste processing equipment, such as a plastic washing machine, plastic dryer, plastic extruder machine, and other equipment to build a complete plastic waste recycling line.

Plastic washing line: The plastic bag crusher machine can also be used in conjunction with a plastic bottle washing line for the production of PET flakes.

If you would like to know more about our plastic shredder recycling machines, please feel free to contact us.

Raw materials of Plastic Film Shredder Machine

The plastic bag crusher machine is mainly used to process various types of plastic waste, including:

- Plastic Bags and Films: Supermarket shopping bags, food packaging films, etc.

- Plastic Packaging Waste: Various types of plastic packaging waste.

- Plastic-coated cardboard: for example, the outer packaging of disposable drinking cups.

Advantages of Woven Bag Shredder

- Efficient processing: waste film crusher machine can quickly cut plastic bags and other soft plastic waste into small particles, improving the efficiency of waste disposal.

- Reduced Volume: After shredding, the volume of plastic bags is significantly reduced to save storage and transportation space.

- Multifunctionality: Plastic film shredder machines can be adapted to different types of plastic waste, such as plastic film, packaging materials, and so on.

- Fine particles: Plastic bag crusher machines can realize precise cutting and generate uniform plastic particles, which are conducive to subsequent reprocessing and utilization.

- Customization: According to different customer needs, the plastic bag shredder can be customized to meet different capacities and processing requirements.

Plastic Film Shredder Export Markets & Customer Feedback

The crusher SLSP-800 installed in Côte d’Ivoire has successfully helped the local recycling factory to efficiently process all kinds of plastic waste, with stable operation and powerful crushing, and the customer’s feedback is that the production capacity has doubled, and the material discharged is even, which has greatly improved the overall production efficiency.

Typical Customer Cases:

- Country: Côte d’Ivoire

- Product: Plastic Crusher

- Application: HDPE Drums + Woven Bags

- Result: 45% increase in crushing efficiency

Customer Reviews:

“The machine runs smoothly with strong cutting force. Even tough plastic materials are crushed easily and evenly.”— Mr. Daniel Kouassi, Operations Manager at EcoPlast Côte d’Ivoire

FAQs of Plastic Waste Crushing Machine

How often does it need to be sharpened or replaced?

Depending on the hardness of the material and the output, it is generally recommended to check for wear 1-2 months.

Can this crusher be plugged into an entire recycling line?

Of course. It can be used with conveyor belt, washing tank, dewatering machine, granulator, etc., to form a complete plastic recycling line.

How is the machine shipped? Is it complicated to install?

Machines are usually shipped in wooden crates or protected by wrap-around film. Installation is very easy, just need to connect the power, confirm the direction of rotation of the cutter shaft, and then it is ready to run. We also provide installation video instructions.