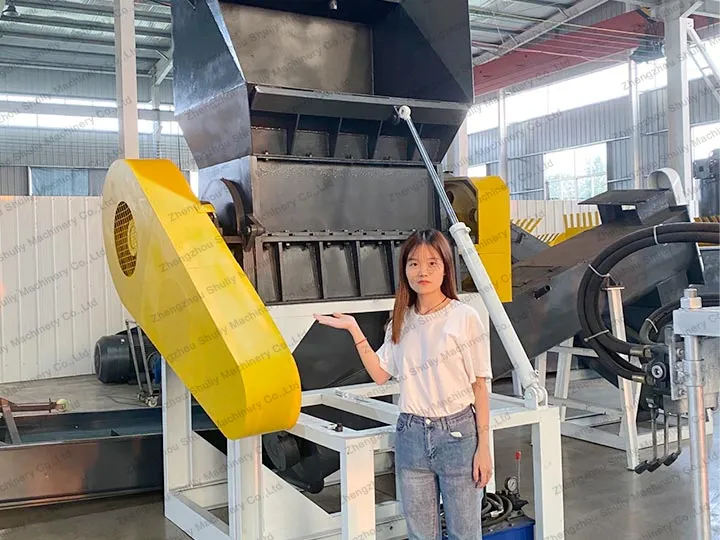

The hard plastic grinder, an important part of the plastic pelletizing line, is equipped with a small aperture screen, which can effectively crush and output waste plastic. We offer 200kg/h, 500kg/h, 800kg/h, and 1000kg/h rigid plastic crushing machines for your choice.

The hard plastic grinder is a specialized machine designed to efficiently process rigid plastics such as HDPE, PP, ABS, and PC. Unlike soft plastic shredders, this grinder features robust rotary blades and a powerful motor to handle tough materials with high hardness and density. It is widely used in industrial recycling to reduce plastic waste volume and prepare materials for further processing like pelletizing.

Hard plastic grinder working principle

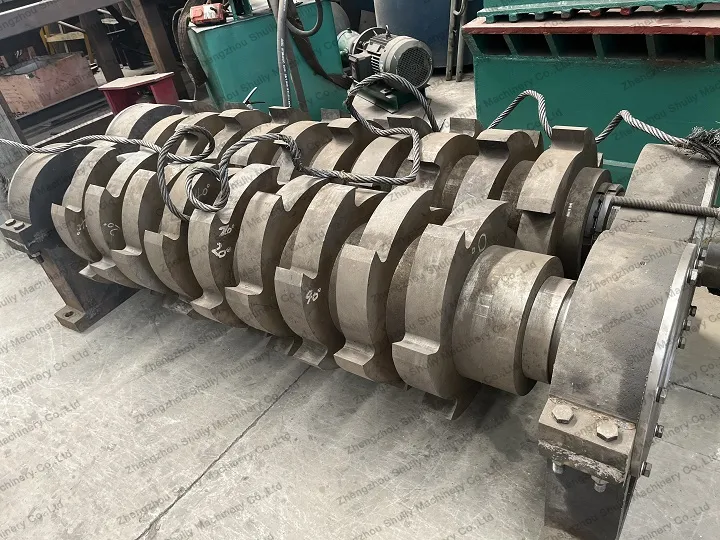

The hard plastic grinder is based on the principle of high-speed rotating blades that effectively break down hard plastic materials into smaller pieces. The precision-designed blades of the HDPE plastic shredder machine ensure efficient cutting, crushing, and grinding of the plastic, ultimately producing small pieces of plastic.

It consists of rotating blades mounted on a rotor and stationary blades fixed on the machine frame. When the motor is powered on, the rotor spins at high speed, and the rotating blades shear the plastic materials against the fixed blades, breaking them into small flakes. A screen at the bottom controls the size of the output flakes, allowing only particles of the desired size to pass through.

Main components:

- Rotor with rotary blades

- Fixed blades

- Electric motor

- Screen mesh

- Hopper and discharge port

Crushing Cycle:

- Feed hard plastic into the hopper

- Rotor spins and blades begin cutting

- Material is sheared between rotary and fixed blades

- Crushed flakes pass through the screen

- Uniform output is collected below

Working Video of the HDPE Plastic Shredder Machine

Want to see the crusher in real operation? Check out this video demonstration where the machine crushes rigid plastics like HDPE and ABS effortlessly. The strong rotary blades and powerful motor guarantee efficient and uniform crushing.

Core Parameters of Hard Plastic Crusher

| Product Model | 800 Heavy – Duty | 600 Heavy-Duty | Values |

| Overall Dimensions | 1500*1800*2000 | 1500*2000*2020 | Adaptable to different recycling plant spaces, small size, flexible layout, large size to carry high capacity. |

| Blade Specifications | 6 Moving Knives, 4 Stationary Knives | 15 Moving Knives, 2 Stationary Knives | The dynamic knife synergy affects the uniformity of the rigid plastic sheet, adapting to different recycling fineness requirements. |

| Motor Power | 45KW | 55KW | Matching processing capacity, small power to control costs, high power to meet the needs of tons of hard plastic recycling |

Recommended Auxiliary Machines for a Complete Hard Plastic Recycling Line

To build a complete and efficient hard plastic recycling system, the hard plastic grinder or hard plastic crusher is typically integrated with a series of auxiliary machines. These supporting units ensure that the crushed plastic materials can be further processed into clean, dry, and reusable plastic granules.

- Plastic washing machine: After crushing, plastic flakes often carry dust, oil, or label residues. A plastic washing tank or friction washer is used to clean the materials thoroughly.

- Dewatering and Drying System: Wet plastic flakes are passed through a horizontal dewatering machine to remove excess moisture, ensuring smooth feeding into the pelletizer.

- Plastic Pelletizing Machine: The dry and clean plastic flakes are fed into a plastic pelletizing machine, where they are melted, extruded, and cut into uniform plastic pellets.

What Plastics Can be Processed in a Rigid Plastic Crushing Machine?

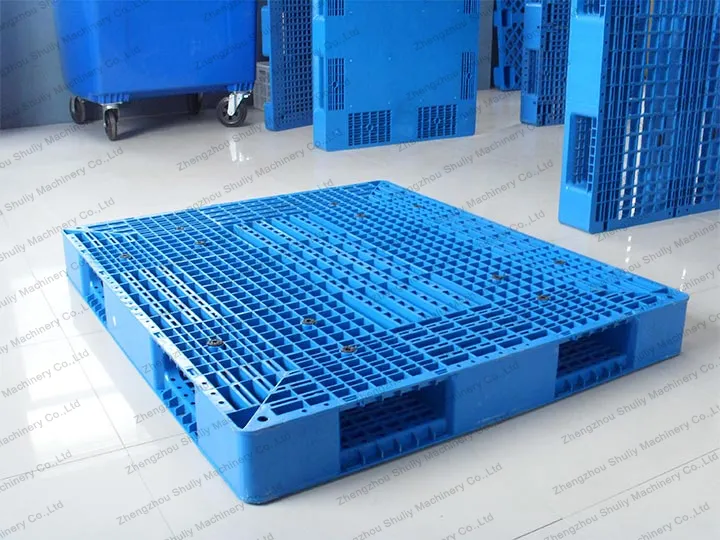

Hard plastic grinders are primarily designed to process plastics such as HDPE, PVC, ABS, PS, and PE. These plastic materials are commonly used in a variety of applications, ranging from plastic pipes and bottles to packaging materials.

Final Product of the Hard Plastic Crushing Machine

The finished product of an HDPE plastic shredder machine is usually plastic chips. During the processing of a hard plastic pulverizer, the rigid plastic material is cut into small pellets. These plastic chips can be used as recycled plastic feedstock for the manufacture of new plastic products.

This recycled utilization helps reduce the need for new plastics and promotes a sustainable plastics circular economy. By converting hard plastic waste into plastic pellets, Hard plastic crusher machines play an important role in plastic waste processing and resource recovery.

Successful Cases of the Plastic Bumper Shredder

Many customers worldwide praise the hard plastic grinder for its powerful crushing ability, stable operation, and energy efficiency. For example, a Kenyan recycling company reported doubling its throughput of HDPE waste after switching to our machine.

A key customer from Ghana purchased a plastic bumper shredder to solve their plastic waste management challenges. By using our machine, they were able to cut their plastic scrap into small pieces that were later used as raw material in their plastic pelletizing machine.

If you also want to get into the plastic recycling business, feel free to leave us a message. We offer plastic recycling solutions.

FAQs You may want to Know about Hard Plastic Crushers

1. What types of hard plastics can a rigid plastic crushing machine handle?

The HDPE plastic shredder machine is suitable for processing hard plastics such as HDPE, PVC, ABS, and PS, which are commonly found in various industrial applications.

2. Are the plastic pieces resizable?

Yes, the hard plastic grinder allows the size of the output plastic pellets to be adjusted.

3. How does the HDPE plastic shredder machine ensure safety during operation?

The rigid plastic crushing machine is equipped with safety features such as an emergency stop button and protective housing to ensure safe operation.

4. Is technical support for the hard plastic grinder provided after purchase?

Yes, our dedicated technical support team will be on hand to help.