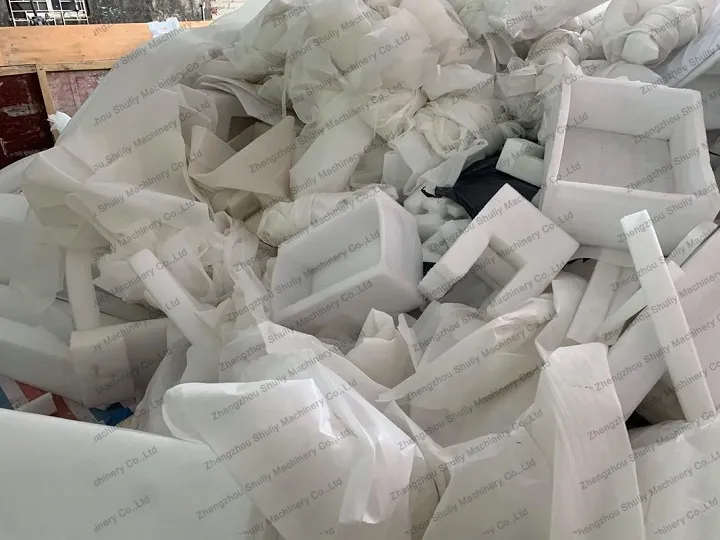

Plastic foam pelletizing line is a solution designed for plastic foam recycling and granulation. In recent years, foam has been widely used in the packaging industry, but it is large and difficult to transport. This has led to the rapid development of foam recovery and recycling machinery and equipment. With the continuous adoption of new technologies, the equipment technology and production efficiency of expanded polystyrene recycling machines have generally been rapidly improved.

Introduction of Plastic Foam Pelletizing Line

The plastic foam pelletizing line efficiently recycles waste foam via compacting, crushing, heating, melting, extrusion, and pelletizing, which features high output, low energy consumption, stable operation, suitable for polystyrene, etc., turning scraps into reusable pellets to boost resource utilization and environmental protection.

Expanded polystyrene pelletizing machine for plastic foam recycling is an integrated industrial system designed to recycle waste plastic foam into reusable plastic pellets. This process transforms low-value, bulky foam waste into high-quality raw materials for new plastic production. The line typically combines mechanical crushing, thermal melting, and pelletizing technologies to achieve efficient material recycling, addressing both environmental pollution and resource scarcity challenges.

Working Video of EPS Foam Recycling and Pelletizing

Process Flow of Plastic Foam Pelletizing Line

Crushing – lumping – drawing – cooling – pelletizing

The plastic foam pelletizing line is 100% available for recycled foam. EPS EPE foam is compressed and then pelletized, making it the most widely recycled processing method. The foam is compressed or thermally melted by a professional foam compressor, which results in a compressed block. The shredded foam compressed blocks can be used for pelletizing to produce high-quality EPS EPE pellets. It can be applied to the production of new foam products. Now, with the growing popularity of carbon emission reduction, recycling has become the primary method for regenerating EPS.

There are some differences between EPE and EPS pelletizing in the EPE EPS foam granulating line. EPE foam is soft, and the granulator to process this kind of foam usually contains an automatic feeding device. Also, the EPE foam doesn’t need a crusher for pre-processing, so that it can be directly put into the granulator.

EPS foam is usually large size, which means EPS foam needs to be shredded by a crusher and compacted. As a result, this kind of foam can enter the granulator for processing.

Main machines of Plastic Foam Granulator Line

Plastic foam crusher

The plastic foam crusher is used to crush large pieces of recycled foam into small pieces that can be easily melted and pelletized.

Foam compactor machine

Due to the low density and large volume of the foam, it needs to be compressed by the foam compactor machine after crushing to improve the material transportation efficiency.

Plastic foam extruder

The plastic foam extruder is used to melt and extrude small pieces of crushed plastic foam into long strips.

Cooling tank

The cooling tank is used to cool down the high-temperature plastic strips to make them harden for cutting easily.

Plastic granule cutter

The plastic granule cutter is used to cut long strips of cooled and hardened plastic into uniformly sized plastic pellets.

The concrete configuration of the EPS foam granulating line can be adjusted according to the personalized requirements of the customers. Feel free to contact us, and we will tailor perfect recycling solutions for you.

Raw Materials and Finished Products of Plastic Foam Pelletizing Line

The plastic foam pelletizing line can make plastic granules from recycled waste foam.

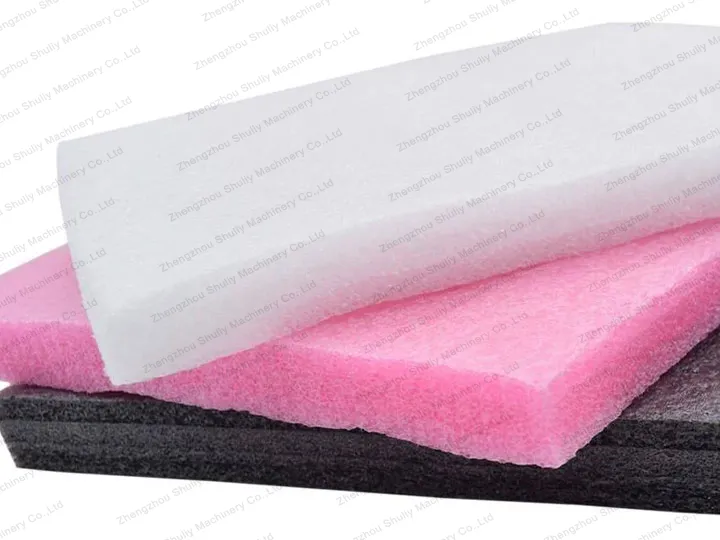

Expanded Polyethylene

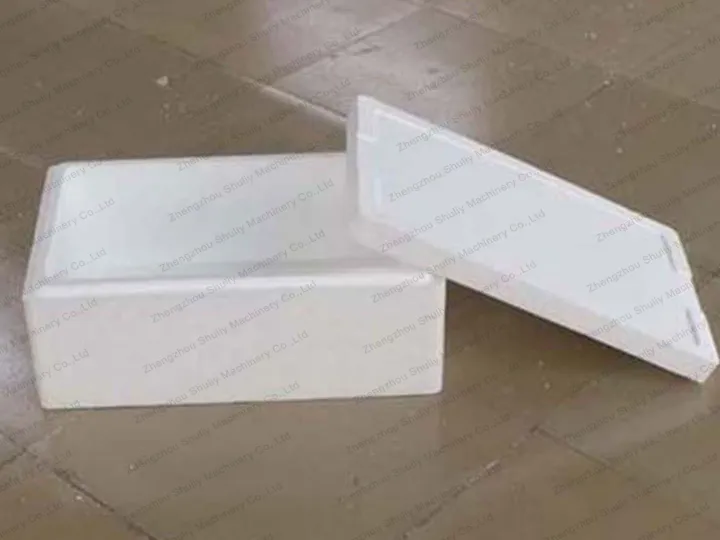

Expanded Polyethylene is a structural foam made from polyethylene polymers. It is manufactured by heating and compressing the polyethylene polymer to form air bubbles that make it lightweight, flexible, and with acoustic and thermal insulation properties. It is mostly used in packaging, construction, and household applications.

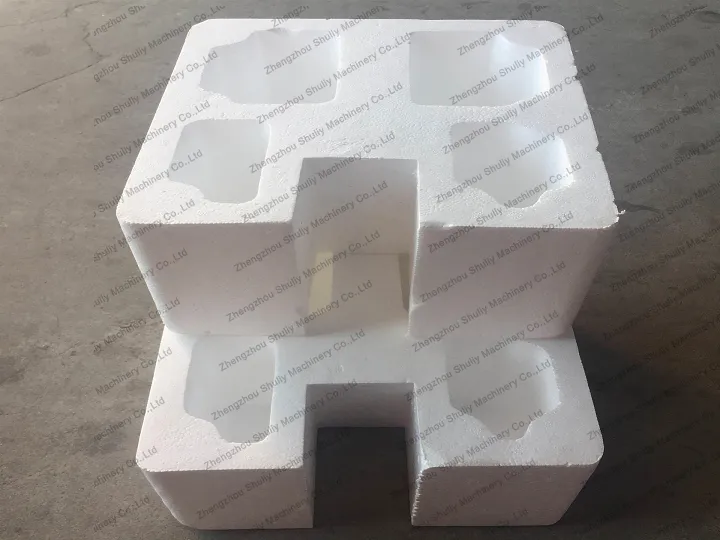

Expanded Polystyrene

EPS, or expanded polystyrene, is a lightweight, rigid, and thermocouple material made from small pellets of polystyrene. EPS is commonly used for insulation, packaging, and protective cushioning applications because of its low cost, versatility, and good insulation properties.

To manufacture EPS, small particles of polystyrene are mixed with an inflator, such as propane, and then heated and molded into large blocks. The inflator forms small bubbles inside the pellets, causing them to expand and form an organism. Depending on the desired application, the expansion process can be controlled to produce EPS with different densities and physical properties.

If you are not very sure about whether the existing materials you have can be pelletized in the EPE EPS foam granulating line, feel free to leave a message on our website. We will contact you in time.

Applications of Recycled Plastic Pellets

EPE EPS material is widely used in the following fields because of its lightweight, elasticity, moisture-proof, shock-proof, and corrosion-resistant properties.

- Packaging: It is often used for packaging electronic products, food, cosmetics, industrial, and other items to protect them from damage during transportation.

- Construction: Foamed polyethylene is often used in construction, such as for wall partitions, sound insulation, thermal insulation, protection, etc.

- Furniture: It is commonly used in the manufacture of furniture such as sofas, seats, mattresses, pillows, etc., to provide comfort and good support.

- Sports equipment: It is often used for the dry manufacturing of sports equipment such as diving boards, protective gear, etc.

- Electronics: It is often used to dry-manufacture electronic products, such as cell phone cases, computer bags, photographic equipment, etc.

Features of Plastic Foam Pelletizing Line

The expanded polystyrene recycling machine is used for recycling and granulating EPE and EPS foam. It is especially suitable for material sorting and turning waste into treasure.

- High Production Capacity: The plastic foam pelletizing line, boasting a production rate of 250 kg/h, ensures efficient handling of large-scale foam waste processing.

- Technological Design & Aesthetic Protection: The plastic foam pelletizing line adopts the latest technology, the appearance with a protective cover that is generous and beautiful, and easy to use.

- Automated Continuous Production: The plastic foam granulator line can realize automatic, continuous production.

EPE EPS Foam Granulating Line Export Case

In 2025, a forward-thinking Mexican plastic recycling firm opted for Shuliy’s SL-180 EPE Styrofoam Pelletizing Machine. Facing the challenge of handling substantial EPE sheets and foam packaging waste, the client needed an efficient solution to convert this bulky material into valuable pellets. The SL-180 line, with its 250 kg/h output capacity, robust build, and user-friendly design, proved ideal.

The exported SL-180 EPE Pelletizing Line with a production rate of 250 kg/h helps the Mexican client boost recycling efficiency, reduce landfill waste, and create a new revenue stream by selling high-quality pellets.

FAQs of Plastic Recycling Machine

What is the typical production capacity of the EPE, EPS Foam Granulating Line?

The plastic foam pelletizing line boasts a production rate of 200-250 kg/h, depending on your raw material.

If you would like more detailed information, please feel free to contact us.

Can wet foam be pelletized directly in the plastic foam pelletizing line?

No. Moisture causes bubbles in the melt and cracked pellets; it must be dried via hot air or centrifugal dehydration.

Why do pellets discolor?

In a plastic foam pelletizing line, possible causes may be extrusion temperature too high (plastic degradation), raw material contamination, or clogged filters. Check temperature control and clean impurities.