With the rise of plastic pollution and foam disposal, we need to know some common sense about styrofoam recycling. We’ll tell you all you need to know about the fundamental issues about foam recycling.

Does styrofoam harm the environment?

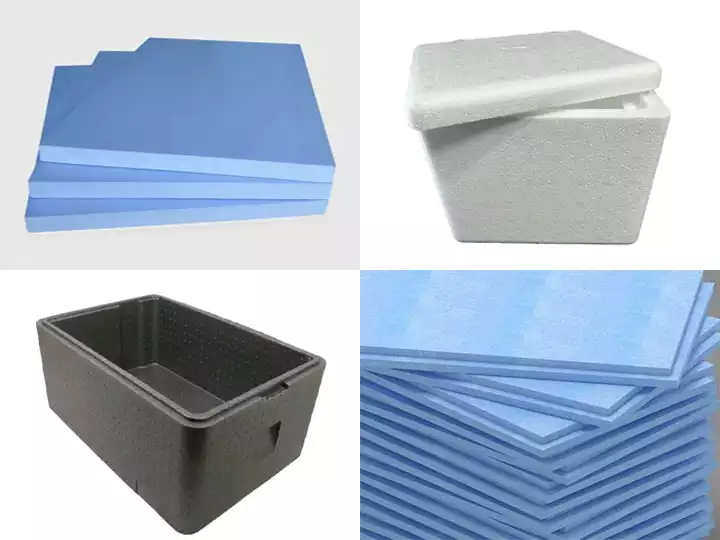

Foam product disposal like plates, egg cartons, cups, packaging inserts, packing peanuts, coolers, etc. are harmful to the environment. The environmental impacts of discarding EPE (Expanded Polyethylene) and EPS (Expanded Polystyrene) foam include the following:

Difficult to degrade: EPE and EPS foams are both plastic materials that can take hundreds of years to degrade. This means that they remain in the environment for a long time, causing accumulation.

Microplastic pollution: Over time, these foam materials break down into tiny particles that become microplastics, which enter soil and water bodies and affect ecosystems.

Waste of resources: The production of EPE and EPS consumes non-renewable resources such as petroleum, which cannot be recycled when discarded, resulting in a waste of resources.

Greenhouse gas emissions: EPE and EPS release greenhouse gases during production, transportation and incineration, contributing to global warming.

What’s the styrofoam recycling process?

Mechanical recycling

- Shredding: Shredding of waste foam material into small pieces for subsequent processing. This step can be done efficiently using specialized styrofoam shredders.

- Pelletizing: The crushed foam particles are processed through a pelletizing machine to be converted into recycled pellets that can be easily reused in production.

- Hot Melt Densification: Through a hot melt densifier, the crushed foam is heated to a molten state, removing the air from it and thus reducing its volume (typically up to a 90:1 compression ratio) for easy storage and transportation.

- Cold compression: The loose foam material is put into a styrofoam compactor, which compresses the foam into blocks by means of a hydraulic system, reducing its volume (usually up to a compression ratio of 60:1) for subsequent handling or transportation.

Chemical recycling

Dissolving and remolding: specific chemicals are used to dissolve the foam, converting it to a liquid state, which is then subjected to a remolding process to generate a new plastic product. This method can handle foam materials that are difficult to recover mechanically.