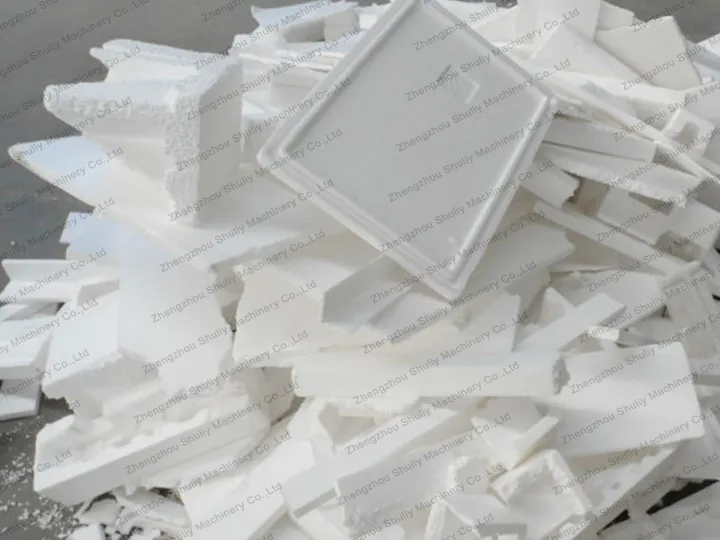

The foam melting machine is also called a styrofoam densifier. It’s used to transform the waste foam into lumps to reduce the volume and facilitate transportation. With easy operation and high output, the styrofoam melting machine is your ideal waste foam recycling equipment. The EPS densifier hot melting machine has the advantage of low input cost and high income.

Introduction of Styrofoam Densifier

The styrofoam densifier melting machine is designed to solve the problem of dry foaming EPE foam scrap capacity reduction by crushing, hot melting, and extrusion molding. It is simple in design, compact in structure, and low in maintenance cost.

Working Principle of the Foam Densifier for Sale

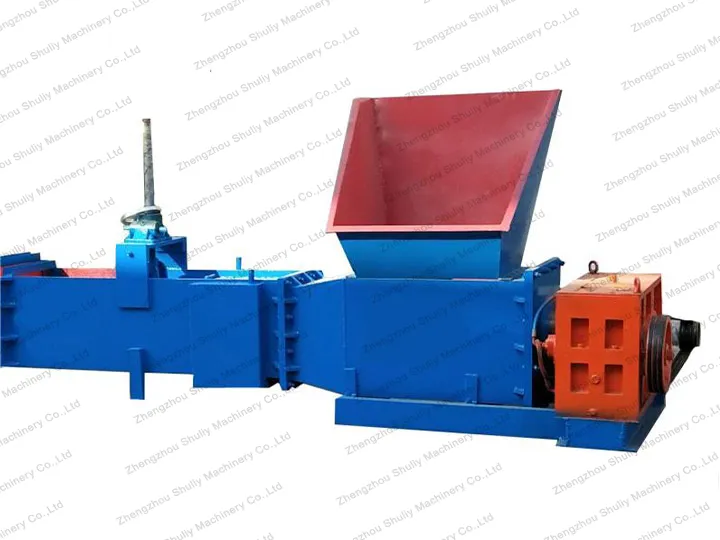

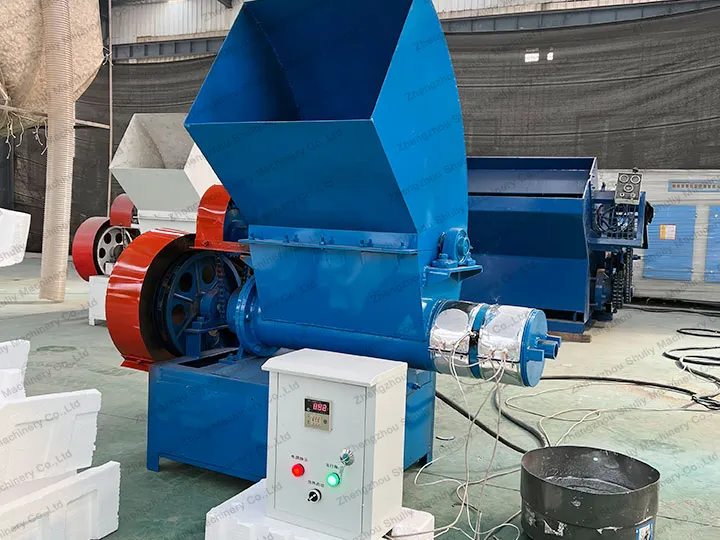

An EPS densifier hot melting machine is a kind of special equipment for foam recycling, mainly used for processing thermoplastics into foam-like objects. The EPS hot melting machine’s working principle is to melt the solid plastic by heating it inside the machine to form a foam-like object. While heating, a high-speed rotating screw pushes the material forward to form a continuous production process.

Feeding:

Loose foam is manually or automatically fed into the hopper.

Pre-crushing:

Foam is shredded to reduce size and increase compression efficiency.

Compression:

EPS is compressed or melted and extruded into dense blocks.

Cooling & Stacking:

The blocks cool quickly and are ready for stacking or baling.

Components of a Polystyrene Densifier

The foam melting machine is mainly composed of a heating system, an exhaust system, a foam system, a control system frame, and other parts. Among them, the heating system is the core part, which mainly consists of an electric heater, a temperature controller, a heat transfer pump, etc.

| Components of EPS hot melting machines | Functions |

| Feeding Hopper | Wide-mouth hopper supports manual or conveyor feeding of loose foam. |

| Compression Chamber | Reinforced steel housing with screw or hydraulic compression system. |

| Main Screw Shaft | Alloy-steel shaft for long-life, continuous torque under high loads. |

| Block Outlet | Output EPS blocks with adjustable size, shape and density. |

The exhaust system is used to eliminate the exhaust gas and water vapor inside the machine to ensure the stability of the production process.

All components of our industrial styrofoam densifier are made from wear-resistant and high-strength materials to ensure long-term stability and low maintenance.

Integration of Styrofoam Melting Machine into Automated Recycling Lines

The styrofoam densifier is not only effective as a standalone machine, but also plays a crucial role in fully automated EPS foam recycling systems. By integrating it with upstream feeding and crushing units, and downstream conveying or pelletizing machines, users can build a plastic foam pelletizing line.

EPS Foam Crusher

Crushes foam into small pieces before densifying.

EPS Pelletizer

Converts compressed foam into plastic granules.

Application of Styrofoam Melter

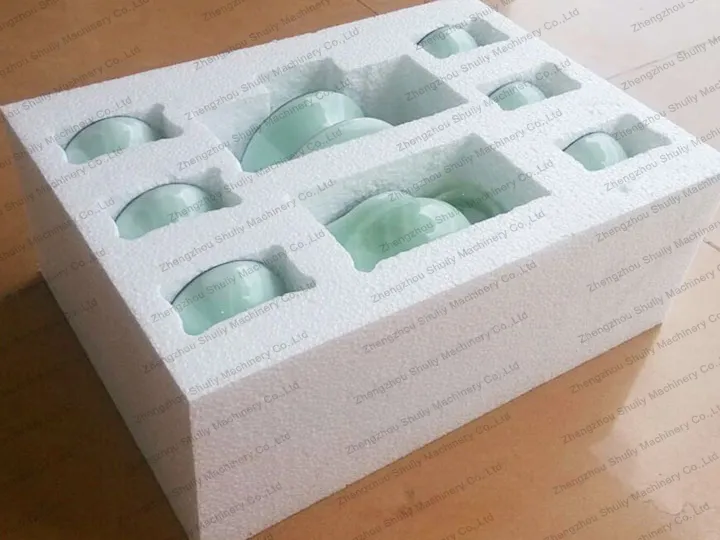

The EPS hot melting recycling machine can recycle and process waste foam produced by industry, construction, packaging, and other industries.

Difference between a Styrofoam Melter and a Foam Compactor Machine

Whether it is a foam melting machine or a foam compactor machine, the ultimate goal is to compress the volume of foam. The main difference is that one melts the foam by heating, and the other processes the foam into blocks by extruding.

The material of the foam is different; if you choose the styrofoam melting machine, some pungent gas will be released at high temperatures. Some customers are resistant to this point, so you should also pay attention when choosing. To say that the compression ratio is clear that the completely melted hot melt machine is better.

Advantages of the Styrofoam Melting Machine

EPS hot melting recycling machine has the advantages of high production efficiency, short production cycle, and low production cost. In recent years, with the increasing awareness of global environmental protection, the environmentally friendly foam materials produced by EPS hot melting recycling machines are also more and more favored by the market.

With the further development of society, the application field of EPS hot melting machines will be gradually expanded, and the technology level will be improved.

If you want to recycle foam but don’t know what machine to choose, drop us a line on the website. We will design a complete solution for you.

FAQ of Polystyrene Densifier

How do I choose the right styrofoam densifier model?

Based on your material type, daily output, and space. We can help calculate the match.

Can the machine handle dirty or wet styrofoam?

We recommend clean and dry EPS for best performance. Wet foam may clog the screw.

How is the machine packaged and shipped internationally?

Machines are packed in standard export wooden cases or wrapped in stretch film for container loading.